TS-300

| Model Name | TS-300 |

| Weight | 397g = 124g + 273g |

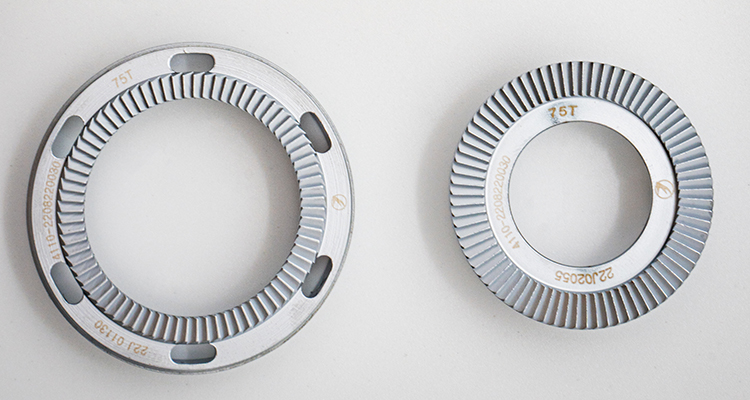

| Engagement Teeth | 75T star ratchets |

| Material of ratchet | Cr-Mo Ti |

| Material of freehub body | Alloy 7075-T6 |

| Material of hub shell | Alloy 6061 |

| Material of hub axles | AL-7075 |

| Sealed Bearings | Front: 17287-2RS * 2 ; Rear: 6902-2RS * 4 |

| Hole Diameter | 2.6mm |

| Gauge | 14G |

| Brake | center lock disc brake |

| Hub holes | 24H / 28H |

| Spoke Type | Straight pull |

| Conversion Kits | Front: M9(QR) x100mm / 15x100mm ; Rear: M10(QR) x135mm / 12x142mm |

| Anodized Colors | black, red, blue, gold, purple, green, pink, orange, silvery, Ti grey, rainbow |

* We asked a bike team tested the new hubs for more than one year, and meanwhile we did some modifications.

* TS-300 hubs are with 75T ratchet which make the engagement very fast, so they perform the best when climbing.

* ECC bike hubs are used Japanese Multemp professional liquid grease --- high lubricity.

* The gorgeous anodized surface won't fade even in 170℃ high temperature baking for 7 hours.

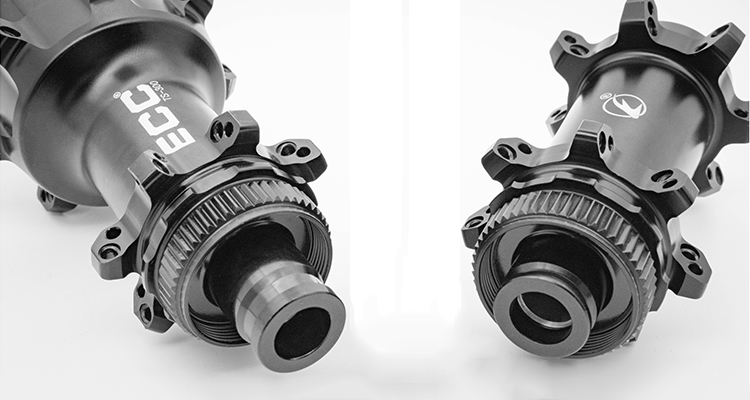

* Easily convert between axle configurations with side caps change, tool free.

* ECC hubs are popular for the high quality & fast engagement and lower price.

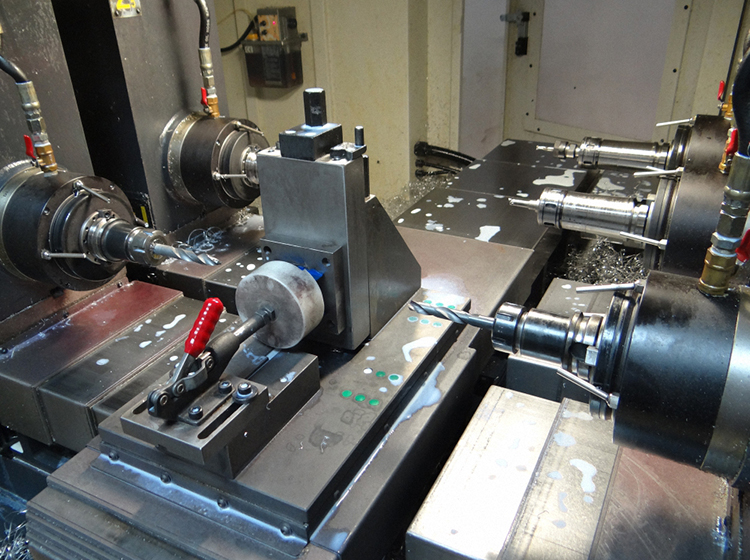

- The teeth parts are made of CRMNTI material, using cold forging forming technology and CNC five axles precision machining process. Imported high-end heat treatment equipment for hardening treatment.

1: The engagement area of 75T provides you with a direct sense of force.

2: The dense 75T arrangement greatly shortens the empty section distance, providing prompt acceleration experience.

3: The stentorian 75T ratchets sound brings a different audio-visual experience.

4: The single body vibrating engagement way makes the 75T ratchet react quickly and sensitively.

5: Quick and detachable freehub body makes maintenance easier.

6: The teeth parts were adopted cold forging technology to improve wear resistance and toughness.

7: The teeth parts use five axles CNC high-precision machining, achieving 1:1 complete engagement.